New South Wales (NSW) has made considerable strides in increasing the proportion of renewable energy in its electricity supply in recent years. Specifically, between 2015 and 2020, the amount of wind and solar energy in NSW’s electricity generation more than doubled.

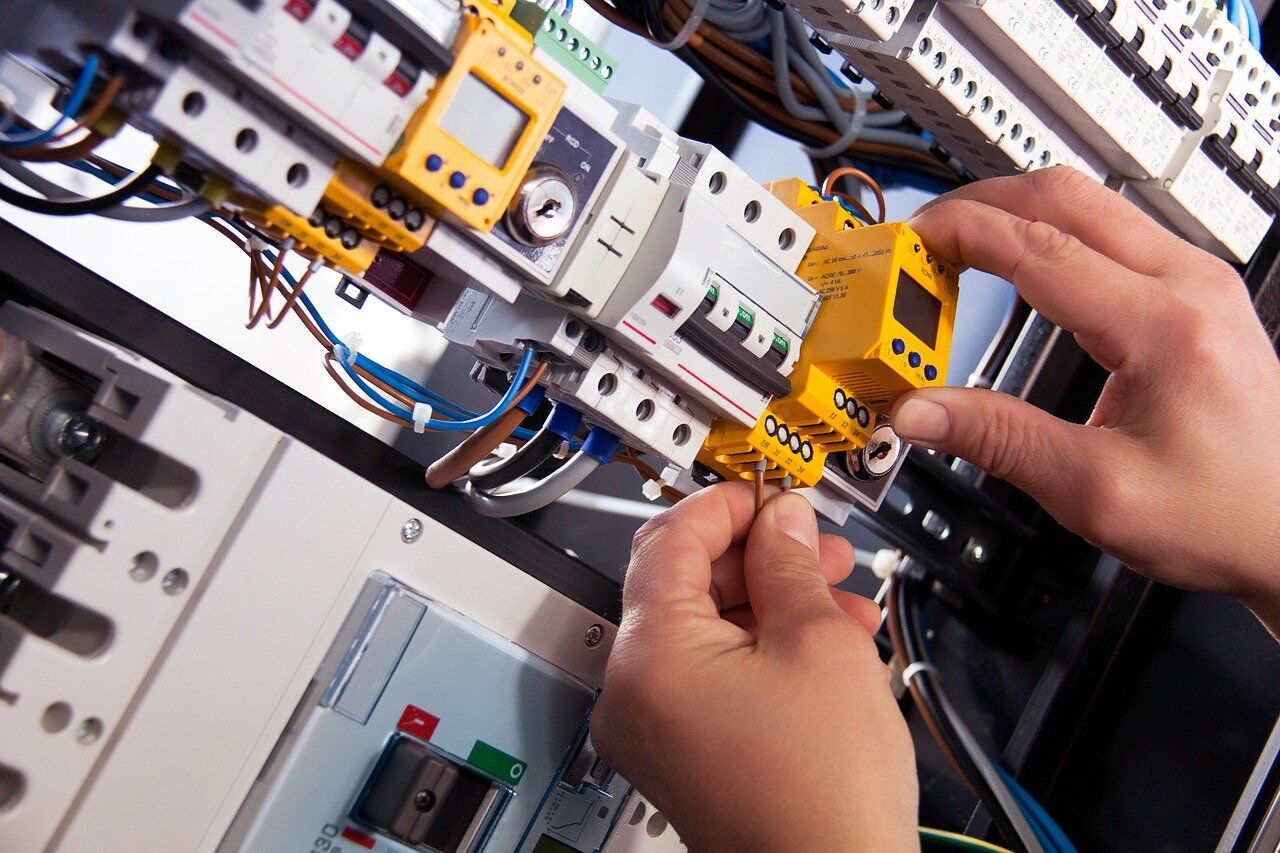

Hunter Valley industrial electricians are critical in ensuring that electrical systems in factories, manufacturing plants, and other industrial settings are running smoothly. Regular maintenance is essential for keeping equipment operating optimally and preventing costly downtime. The following points will explore the benefits of regular maintenance.

Increased Equipment Reliability

Regular maintenance can significantly increase the reliability of industrial equipment. Electrical systems are subject to wear and tear over time, leading to malfunctions and breakdowns. Routine maintenance can help identify potential problems before they cause equipment failure, ensuring that your machinery remains operational and preventing costly downtime. By identifying and fixing issues early on, industrial electricians can help prevent unexpected breakdowns and extend the lifespan of the equipment.

Improved Safety

Safety is a top priority in any industrial setting. Electrical systems that are not properly maintained can pose a significant risk to workers. Regular maintenance can identify and correct potential safety hazards such as frayed wires, faulty electrical components, and improperly installed equipment. By addressing these issues before they become major safety concerns, industrial electricians can help prevent accidents and injuries in the workplace.

Reduced Energy Consumption

Industrial electricians can help reduce energy consumption by identifying and correcting inefficiencies in electrical systems. When equipment is not operating optimally, it can require more energy to perform its intended function. Regular maintenance can help identify and correct issues causing energy waste, such as voltage imbalances and power factor issues. By improving the energy efficiency of electrical systems, industrial electricians can help reduce energy consumption and save money on energy costs.

Cost Savings

Regular maintenance can also help save money in the long run. By identifying and correcting potential problems before they cause equipment failure, industrial electricians can help prevent costly repairs and downtime. Additionally, improving energy efficiency can help reduce energy costs. When equipment operates optimally, it can also require less maintenance and fewer repairs, further reducing costs over time.

Compliance with Regulations

Hunters Valley industrial electricians are well-versed in industry regulations and codes that govern electrical systems in industrial settings. Regular maintenance can help ensure that your equipment complies with these regulations, avoiding potential fines and penalties. In addition, adhering to regulations can help prevent accidents and injuries in the workplace, protecting both workers and the company.

By identifying and correcting potential problems early on, industrial electricians can help prevent costly downtime and repairs, reduce energy consumption and costs, and ensure compliance with industry regulations. Companies need to prioritise regular maintenance by qualified industrial electricians to ensure their equipment’s safety, reliability, and longevity.

Furthermore, regular maintenance can also help improve the overall efficiency of industrial operations. Production processes can be completed more quickly and effectively when equipment runs smoothly and efficiently. This can result in increased productivity and profitability for the company.

Industrial electricians can also provide valuable insights and recommendations for optimising electrical systems. By staying up-to-date on the latest industry trends and technologies, they can suggest upgrades and improvements that can further enhance the performance and efficiency of the equipment.

In addition to their technical expertise, industrial electricians possess strong problem-solving and troubleshooting skills. When issues arise with electrical systems, they can quickly and effectively diagnose the problem and develop a solution. This can help minimise downtime and prevent further damage to equipment.

Average Rating